BIO certificate

Valid from 24/02/2025

Valid until 31/12/2026

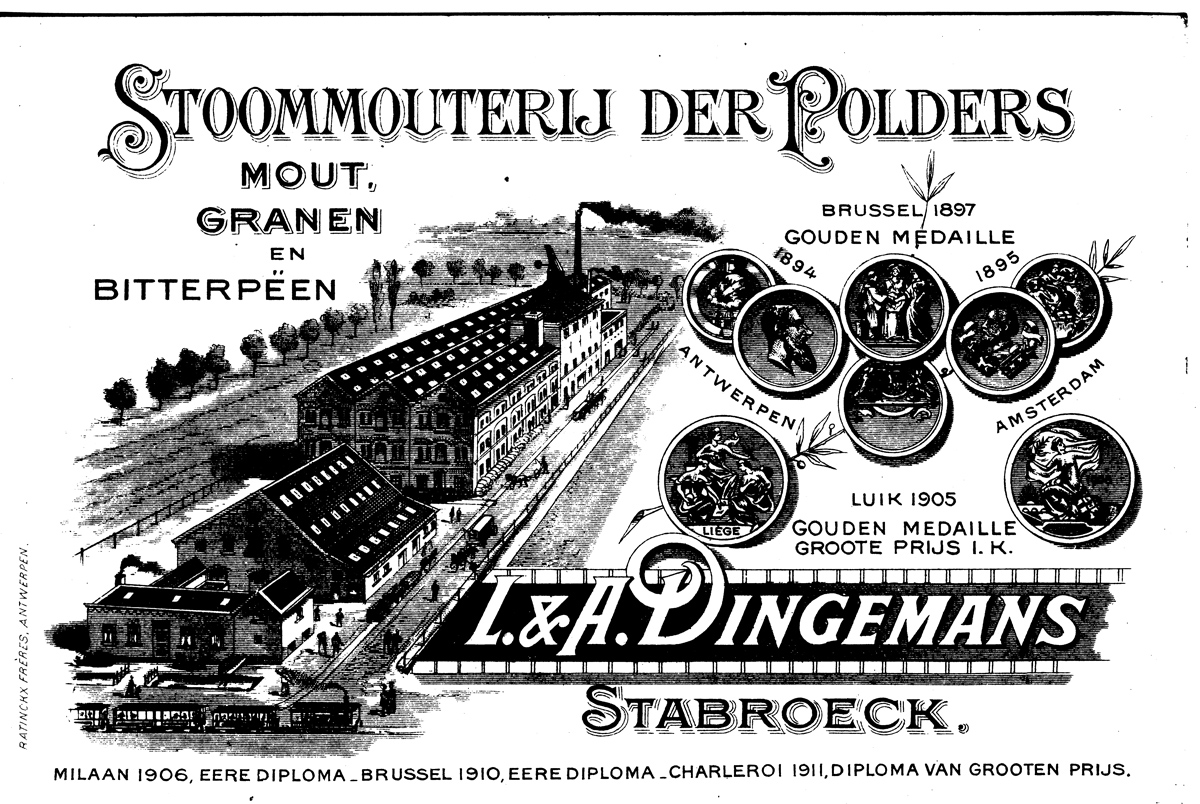

Since 1875, the Dingemans family has been producing an extensive range of basic ingredients for the demanding Belgian and European brewer.

You have probably already tasted some of the great Belgian beers. As a supplier to most Belgian brewers, we are proud of our customers and the great beers they produce. Our malts are used in internationally renowned Trappist, Ale, Lambic, white- and abbey beers.

We are happy and grateful to make our contribution to these beers. Over the years we have distributed our malts further and further. Now brewers all over the world use our great Belgian malts.

We (the Dingemans family) have malting in our blood. We have been a real family business since 1875 and are still 100% independent. The 5th generation is currently active in our malting company. Already more than 10 years ago Karl and Jan Dingemans took over from their father Alfons Dingemans.

3% of our electricity is generated by solar energy.

87% by the CHP’s

AlterBrew

Use of alternative grains for the production of innovative beers from high quality. By alternative grains we mean the ancient wheats such as einkorn, emmer, khorasan (Kamut®), and spelt, the pseudo grains amaranth, quinoa, buckwheat, as well as other grains such as sorghum, tritordeum and teff.

We focus on the malting of Einkoorn and Tritordeum.

With this test we check how much % of the grains can germinate. The grains with a red dot are able to germinate.

We mimic the brewing process in our small mash baths. After filtering, we continue with the wort, on which we performe a complete malt analysis.

Follow-up of the malt germination

With this device we measure the extract content, the viscosity and the pH.

Has worked in the company since 1996. Started as a maltster in the production after which he took over the tasks from his father.

Mainly focuses on barley purchasing, sales and customer relations.

Has worked in the company since 2006. Jan is responsible for production and technical matters in the malt house.

|

BIO certificate

Valid from 24/02/2025 |

Valid until 2026-11-27 |

Valid from 2025-01-01 |

|

Valid from 02-04-2025 |